A composite cutting machine is a machine used for cutting thin sheets of material, such as carbon fiber, into components. These cnc machining machines use specialized software to help design the part and aim their own cuts. Composite machines are very versatile and can be used for a variety of applications, such as aircraft manufacturing, race car manufacturing, and wind turbine blades.

What Is A Composite Cutting Machine?

Nowadays, composites are becoming increasingly popular as a material for a variety of applications. While composites are not new, the development of composite cutting machines has made them more accessible and affordable for the average user.

A composite cutting machine is a specialized piece of equipment that can be used to cut composite materials. They come in different forms and sizes, and can be operated by either hand or machine. A composite cutting machine can be used to cut both standard and advanced composites, and can be used to produce a wide range of shapes and sizes.

There are many reasons why you might need a composite cutting machine. For example, if you want to create custom parts or components out of composite materials, a composite cutting machine can help you do just that. Additionally, if you work with complex or large composites, a composite cutting machine can make the process much easier and faster. Finally, if you want to add some decorative features or patterns to your materials, a composite cutting machine can help you do that as well.

What Are The Various Types Of Cutting Machines?

There are a variety of different types of cutting machines, each with its own specific purpose. Here is a brief overview of some of the most common types:

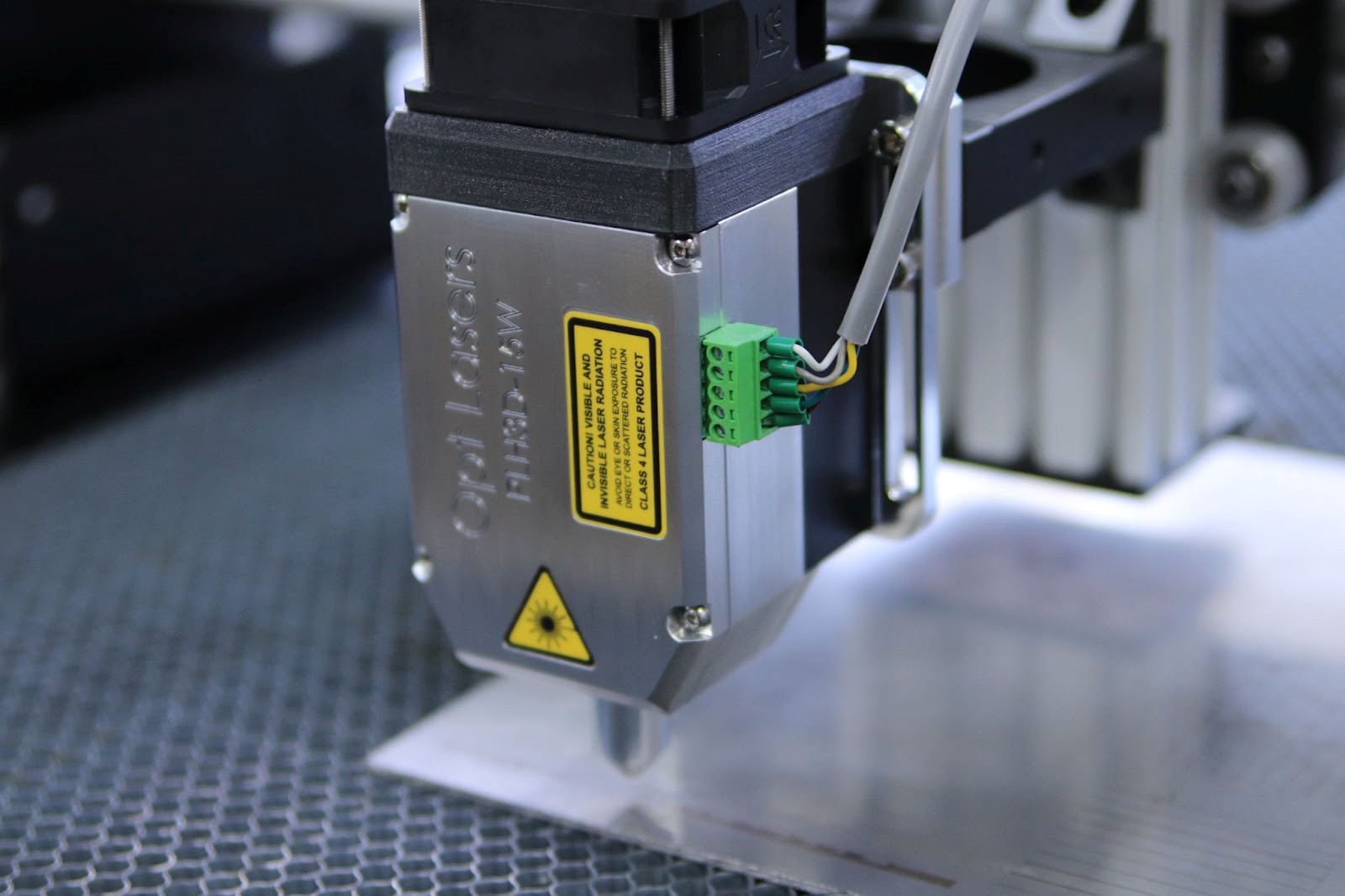

CNC (Computer Numerical Control) Machines

These machines use digital controls to precisely cut parts from a piece of material. They’re used in industries such as manufacturing and engineering, where accuracy and precision are key factors. CNC machines can be very expensive, but their accuracy and versatility make them well worth the investment.

Punching Machines

Punching machines use a set of punches to cut material. They’re often used in woodworking and other construction-related tasks, where quick and easy cuts are necessary. Punching machines are relatively cheap and easy to operate, making them a good option for smaller projects.

Shear Cutting Machines

Shear cutting machines use blades that shear the material instead of cutting it. This results in much less waste than traditional cutting methods, which is especially useful when cutting delicate materials. Shear cutting machines can be quite expensive, but their precision and efficiency make them worth the investment in certain cases.

Different Types Of Cutting Blades

There are different types of cutting blades that are used in composite machines. The main types are:

– Slitter Blades: These blades are used to cut the material very thin. They have many small, sharp teeth that make it easy to cut through the material.

– Shear Blades: These blades are used to shear the material. They have a long, thin blade that is flexible and can move sideways and up and down. This makes it easier to cut through the material.

Why Do You Need One?

The benefits of using a composite cutting machine are countless. Here are just a few reasons why you need one in your workshop:

-They’re incredibly fast and efficient, allowing you to get more work done in less time.

-They’re versatile, being able to cut both soft and hard materials with equal ease.

-They’re very durable, meaning that they can take a lot of punishment without breaking.

-They’re easy to use, requiring minimal training or experience to operate.

Where Can You Get One?

Composite cutting machines are versatile and efficient tools used in a variety of industries. They are often used for cutting composite materials such as fiberglass, carbon fiber, and Kevlar. Composite materials have many unique properties that make them difficult to cut with traditional cutting methods. Theseproperties make composite materials ideal candidates for use in aircraft and other aerospace applications.

There are a few different types of composite cutting machines available on the market. The most common type is called a CNC (Computer Numerical Control) machine. This machine uses a computer to control the motion of the tool and the Cutting Edge. CNC machines are very accurate and can produce very high-quality cuts. They can also be set up to cut multiple pieces at once, which makes them ideal for manufacturing complex parts.

Another type of composite cutting machine is known as an offset machine. Offset machines use a movable bed to position the pieces that you want to cut relative to the blade. This allows you to cut multiple pieces at once without having to move each piece individually. Offset machines are less accurate than CNC machines, but they are faster and easier to use.

Regardless of which type of machine you choose, it is important that you understand how it works before you start using it. You should also be familiar with the various types of blades available on the market and choose one that will work best for your project